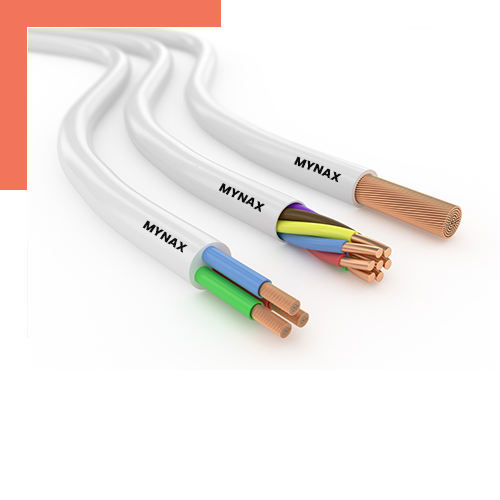

Single Core / Multicore Flexible Cables

Single Core / Multicore Flexible Cables

Application

Mynax Cables are widely used for switchboards, control panel relays, handheld power tools, UPS, Rectifier equipments,

Motor Starters & controllers, power supply cords by OEM’s & in industries.

Product Type

- Single core cables for flexible wiring for indoor, and outdoor installations – 0.50 Sq. mm to 630 sq. mm.

- Multicore Sheathed cables for indoor & outdoor installations – 1 core to 25 cores x 0.5 sq. mm to 50 sq. mm.

- Multi core Sheathed cables for outdoor installations upto 4 core x 300 sq. mm.

Construction

- Conductor– Electrolytic grade high conductive annealed bare or tinned copper flexible conductor class 5 as per IS:8130.

- Insulation – General Purpose PVC insulation (70° C)-Type D

- Cores identification

colour identification

| Colour | Red | Yallow | Blue | Green | White | Black | Grey | Orange | Brown | Pink | Violet |

|---|---|---|---|---|---|---|---|---|---|---|---|

| code | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 Core | All Colors | 7 core | 1,2,3,4,5,6 & Yellow Green | ||||||||

| 2 Core | 1 And 6 | 8 core | 1,2,3,4,5,6,7 & Yellow Green | ||||||||

| 3 Core | 1, 6 & Yellow- Green | 9 core | 1,2,3,4,5,6,7,8 & Yellow-Green | ||||||||

| 4 Core | 1,2,3 & Yellow- Green | 10 core | 1,2,3,4,5,6,7,8,9 & Yellow-Green | ||||||||

| 5 Core | 2,3,4,5 & Yellow- Green | 11 core | 1,2,3,4,5,6,7,8,9,10 & Yellow-Green | ||||||||

| 6 Core | 1,2,3,4,5 & Yellow- Green | 12 core | 1,2,3,4,5,6,7,8,9,10,11 & Yellow-Green | ||||||||

| 13 to 25 Core | Two adjacent cores in each layer Blue & Yellow (reference & direction) & all other remaining cores Grey. (Alternatively from 6 core to 25 core, same color cores, either Black or Grey, with number coded and with Yellow-Green in outermost layer as last core can be supplied). | ||||||||||

Sheath

General Purpose PVC sheath (70°C) – Type ST3 Heat Resistant PVC sheath (85°C ) – Type ST2 Note: FR / FR-LSH or ZHFR Cables can be manufactured against request.

FLAME / FIRE RESISTANCE PERFORMANCE

| S.no. | Test | Standard | Value |

|---|---|---|---|

| 1 | Flammability test | IS: 694 | Extinguish <6 sec and Max decompose 50 mm> |

| 2 | Halogen acid gas evolution | IEC 60754- 1 | < 0.5% for ZHFR and < 20% for FR/FR-LSH cables > |

| 3 | Corrosive gases | IEC 60754-2 | pH - >4.3 and Conductivity < 100 S/cm > |

| 4 | Toxicity index | IEC 60754-2 | Max 5% |

| 5 | Oxygen Index | ASTM D 2863 | Min 29% |

| 6 | Temperature Index | ASTM D 2863 | Min 250 deg C |

| 7 | Smoke density rating | ASTM D 2843 | Max 20% for ZHFR and Max 40% for FR-LSH cables |

Single core Unsheathed cables with Flexible Copper Conductor – General Purpose – 70°C or 85°C

| Nominal Cross sectional area of conductor in Sq. mm | Nominal Thickness of Insulation in mm | Maximum overall diameter in mm | Max. DC Resistence Ohm/Km At 20° C | Current Rating in Amps | Nominal Cross sectional area of conductor in Sq. mm | Nominal Thickness of Insulation in mm | Maximum overall diameter in mm | Max. DC Resistence Ohm/Km At 20°C | Current Rating in Amps |

|---|---|---|---|---|---|---|---|---|---|

| 0.5 | 0.6 | 2.6 | 39.00 | 4 | 35 | 1.2 | 11.7 | 0.554 | 110 |

| 0.75 | 0.6 | 2.8 | 26.00 | 7 | 50 | 1.4 | 13.9 | 0.386 | 145 |

| 1 | 0.6 | 3.0 | 19.50 | 12 | 70 | 1.4 | 16.0 | 0.272 | 215 |

| 1.5 | 0.7 | 3.4 | 13.30 | 16 | 95 | 1.6 | 18.2 | 0.206 | 260 |

| 2.5 | 0.8 | 4.1 | 7.98 | 22 | 120 | 1.6 | 20.2 | 0.161 | 305 |

| 4 | 0.8 | 4.8 | 4.95 | 29 | 150 | 1.8 | 22.5 | 0.129 | 355 |

| 6 | 0.8 | 5.3 | 3.30 | 37 | 185 | 2.0 | 24.9 | 0.106 | 415 |

| 10 | 1.0 | 7.0 | 1.91 | 51 | 240 | 2.2 | 28.4 | 0.0801 | 500 |

| 16 | 1.0 | 8.1 | 1.21 | 68 | 300 | 2.4 | 31.0 | 0.0641 | 585 |

| 25 | 1.2 | 8.1 | 10.2 | 0.78 | 86 | 400 | 2.6 | 32.2 | 695 |

FLAME / FIRE RESISTANCE PERFORMANCE

| Nom. cross sectional area of conductor | Nominal thickness of insulation | Max. DC Resistance At 20° C | Nominal thickness of sheath | Maximum overall diameter | Current Rating in Amps | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 core | 3 core | 4 core | 5 core | 2 core | 3 core | 4 core | 5 core | ||||

| Sq.mm | mm | Ohm/Km | mm | mm | mm | mm | mm | mm | mm | mm | - |

| 0.5 | 0.6 | 39.0 | 0.90 | 0.9 | 0.9 | 0.9 | 6.9 | 7.3 | 8.0 | 8.7 | 4 |

| 0.75 | 0.6 | 26.0 | 0.9 | 0.9 | 0.9 | 0.9 | 7.3 | 7.7 | 8.4 | 9.2 | 7 |

| 1 | 0.6 | 19.5 | 0.9 | 0.9 | 0.9 | 1.0 | 7.6 | 8.1 | 8.8 | 9.6 | 12 |

| 1.5 | 0.6 | 13.3 | 0.9 | 0.9 | 1.0 | 1.0 | 8.9 | 9.4 | 10.4 | 11.4 | 16 |

| 2.5 | 0.7 | 7.98 | 1.0 | 1.0 | 1.0 | 1.0 | 10.3 | 10.9 | 12.0 | 13.2 | 22 |

| 4 | 0.8 | 4.65 | 1.0 | 1.0 | 1.0 | 1.1 | 11.6 | 12.4 | 13.6 | 15.3 | 29 |

| 6 | 0.8 | 3.30 | 1.1 | 1.2 | 1.2 | - | 13.0 | 13.8 | 15.4 | - | 37 |

| 10 | 1.0 | 1.91 | 1.3 | 1.4 | 1.4 | - | 16.5 | 17.6 | 19.5 | - | 51 |

| 16 | 1.0 | 1.21 | 1.4 | 1.4 | 1.4 | - | 19.4 | 20.6 | 23.0 | - | 68 |

| 25 | 1.2 | 0.780 | 1.4 | 1.5 | 1.6 | - | 23.8 | 25.6 | 28.5 | - | 86 |

| 35 | 1.2 | 0.554 | 1.6 | 1.6 | 1.7 | - | 27.2 | 29.3 | 32.7 | - | 110 |

| 50 | 1.4 | 0.386 | 2.0 | 2.0 | 2.0 | - | 32.0 | 34.6 | 38.6 | - | 145 |

| 70 | 1.4 | 0.272 | 2.2 | 2.2 | 2.2 | - | 36.8 | 39.6 | 44.3 | - | 215 |

| 95 | 1.6 | 0.206 | 2.4 | 2.4 | 2.4 | - | 41.8 | 47.0 | 50.2 | - | 260 |

| 120 | 1.6 | 0.161 | 2.5 | 2.9 | 3.1 | - | 46.2 | 51.0 | 55.7 | - | 305 |

Flexible PVC Insulated & Sheathed cirular cables – General Purpose- 70° or 85°C

| No. of Cores | 0.5 Sq. mm Max. CR at 20°C - 39.0 Ohm/Km Current rating - 4 Amps | 0.75 Sq. mm Max. CR at 20°C - 26.0 Ohm/Km Current rating - 4 Amps | 1 Sq. mm Max. CR at 20°C - 19.5 Ohm/Km Current rating - 12 Amps | ||||||

|---|---|---|---|---|---|---|---|---|---|

| - | Nom Ins. Thickness | Nom Sheath Thicknes | Max. Overall Diameter | Nom Ins. Thickness | Nom Sheath Thicknes | Max. Overall Diameter | Nom Ins. Thickness | Nom Sheath Thicknes | Max. Overall Diameter |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| 6 | 0.6 | 0.9 | 9.5 | 0.6 | 1.0 | 10.0 | 0.6 | 1.0 | 10.0 |

| 7 | 0.6 | 0.9 | 9.5 | 0.6 | 1.0 | 10.0 | 0.6 | 1.0 | 10.0 |

| 8 | 0.6 | 1.0 | 11.0 | 0.6 | 1.0 | 11.8 | 0.6 | 1.0 | 12.4 |

| 9 | 0.6 | 1.0 | 11.8 | 0.6 | 1.1 | 12.4 | 0.6 | 1.1 | 13.1 |

| 10 | 0.6 | 1.0 | 12.0 | 0.6 | 1.1 | 12.7 | 0.6 | 1.1 | 13.4 |

| 11 | 0.6 | 1.0 | 12.0 | 0.6 | 1.1 | 12.7 | 0.6 | 1.1 | 13.4 |

| 12 | 0.6 | 1.0 | 12.4 | 0.6 | 1.1 | 13.1 | 0.6 | 1.1 | 13.9 |

| 13 | 0.6 | 1.0 | 13.1 | 0.6 | 1.1 | 13.8 | 0.6 | 1.1 | 14.6 |

| 14 | 0.6 | 1.0 | 13.1 | 0.6 | 1.1 | 13.8 | 0.6 | 1.1 | 14.6 |

| 15 | 0.6 | 1.0 | 13.5 | 0.6 | 1.2 | 14.3 | 0.6 | 1.2 | 15.1 |

| 16 | 0.6 | 1.0 | 13.8 | 0.6 | 1.2 | 14.6 | 0.6 | 1.2 | 15.4 |

| 17 | 0.6 | 1.1 | 14.6 | 0.6 | 1.2 | 15.4 | 0.6 | 1.2 | 16.3 |

| 18 | 0.6 | 1.1 | 14.6 | 0.6 | 1.2 | 15.4 | 0.6 | 1.2 | 16.3 |

| 19 | 0.6 | 1.1 | 14.6 | 0.6 | 1.2 | 15.4 | 0.6 | 1.2 | 16.3 |

| 20 | 0.6 | 1.2 | 15.4 | 0.6 | 1.3 | 16.3 | 0.6 | 1.2 | 17.3 |

| 21 | 0.6 | 1.2 | 15.4 | 0.6 | 1.3 | 16.3 | 0.6 | 1.2 | 17.3 |

| 22 | 0.6 | 1.2 | 16.3 | 0.6 | 1.3 | 17.3 | 0.6 | 1.2 | 18.2 |

| 23 | 0.6 | 1.2 | 16.3 | 0.6 | 1.3 | 17.3 | 0.6 | 1.2 | 18.2 |

| 24 | 0.6 | 1.2 | 17.1 | 0.6 | 1.3 | 18.2 | 0.6 | 1.2 | 19.2 |

| 25 | 0.6 | 1.2 | 17.1 | 0.6 | 1.3 | 18.2 | 0.6 | 1.2 | 19.2 |

Flexible PVC Insulated & Sheathed cirular cables – General Purpose- 70° or 85°C

| No. of Cores | 1.5 Sq. mm Max. CR at 20°C - 13.3 Ohm/Km Current rating -16 Amps | 2.5 Sq. mm Max. CR at 20°C - 7.98 Ohm/Km Current rating - 22 Amps | ||||

|---|---|---|---|---|---|---|

| - | Nom Ins. Thickness | Nom Sheath Thicknes | Max. Overall Diameter | Nom Ins. Thickness | Nom Sheath Thicknes | Max. Overall Diameter |

| mm | mm | mm | mm | mm | mm | |

| 6 | 0.6 | 1.0 | 12.4 | 0.7 | 1.1 | 14.5 |

| 7 | 0.6 | 1.0 | 12.4 | 0.7 | 1.1 | 14.5 |

| 8 | 0.6 | 1.1 | 14.7 | 0.7 | 1.2 | 17.3 |

| 9 | 0.6 | 1.1 | 15.6 | 0.7 | 1.3 | 18.3 |

| 10 | 0.6 | 1.1 | 16.0 | 0.7 | 1.3 | 18.7 |

| 11 | 0.6 | 1.1 | 16.0 | 0.7 | 1.3 | 18.7 |

| 12 | 0.6 | 1.1 | 16.5 | 0.7 | 1.3 | 19.4 |

| 13 | 0.6 | 1.2 | 17.4 | 0.7 | 1.3 | 20.5 |

| 14 | 0.6 | 1.2 | 17.4 | 0.7 | 1.3 | 20.5 |

| 15 | 0.6 | 1.2 | 18.1 | 0.7 | 1.4 | 21.3 |

| 16 | 0.6 | 1.2 | 18.4 | 0.7 | 1.4 | 21.7 |

| 17 | 0.6 | 1.3 | 19.5 | 0.7 | 1.4 | 23.0 |

| 18 | 0.6 | 1.3 | 19.5 | 0.7 | 1.4 | 23.3 |

| 19 | 0.6 | 1.3 | 19.5 | 0.7 | 1.4 | 23.8 |

| 20 | 0.6 | 1.4 | 20.7 | 0.7 | 1.5 | 24.4 |

| 21 | 0.6 | 1.4 | 20.7 | 0.7 | 1.5 | 25.0 |

| 22 | 0.6 | 1.4 | 21.9 | 0.7 | 1.5 | 25.8 |

| 23 | 0.6 | 1.4 | 21.9 | 0.7 | 1.5 | 26.3 |

| 24 | 0.6 | 1.4 | 23.0 | 0.7 | 1.5 | 27.2 |

| 25 | 0.6 | 1.4 | 23.0 | 0.7 | 1.5 | 27.9 |

BEST QUALITY & DURABILITY

We are focused on conveying more than our customerʼs expectations. We strive for merit and excellence in our abilities, individuals, processes and technologies. We accomplish our work in a fair.